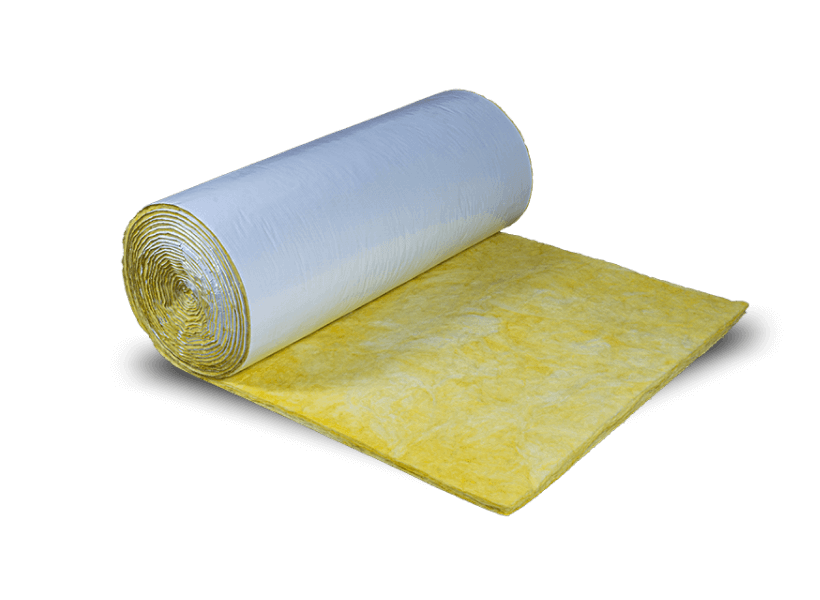

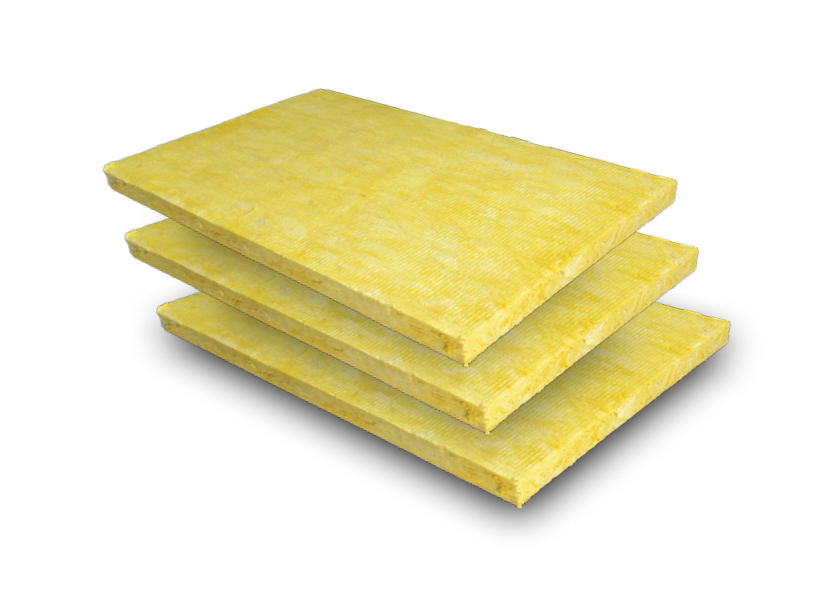

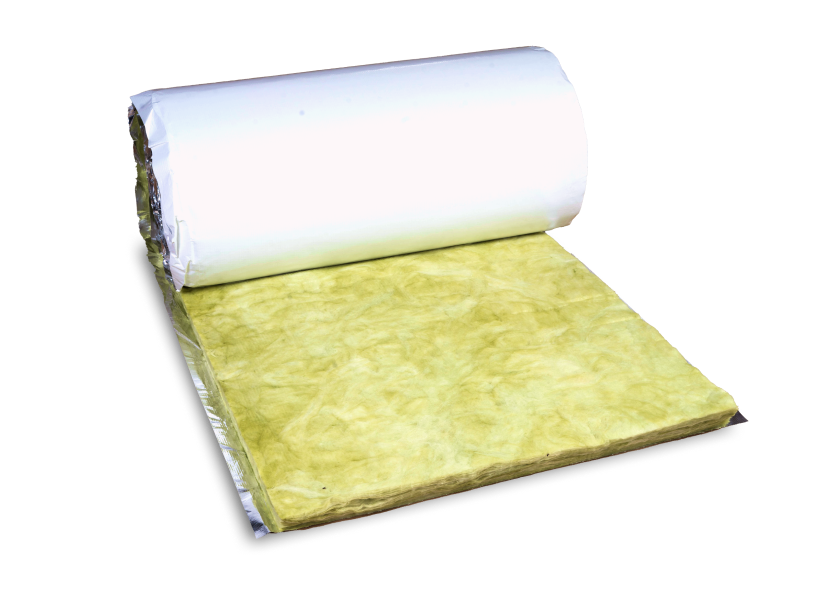

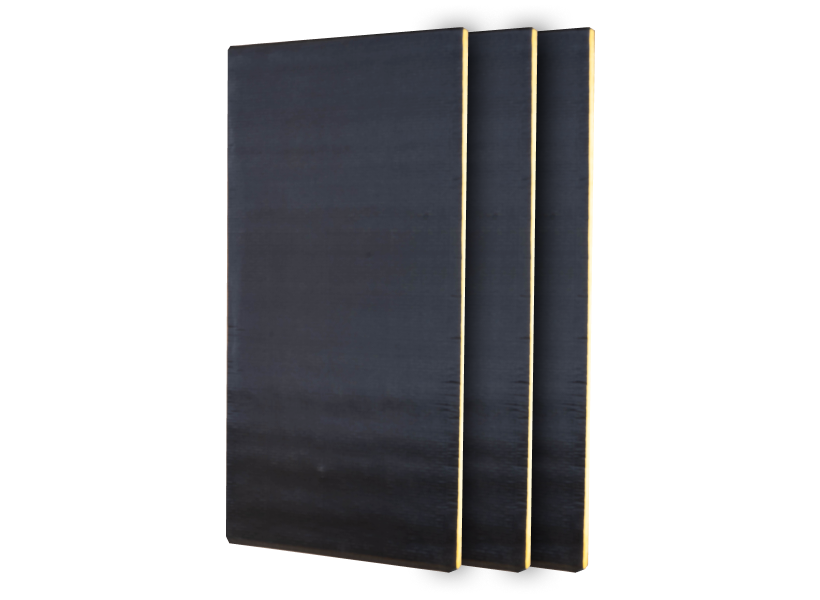

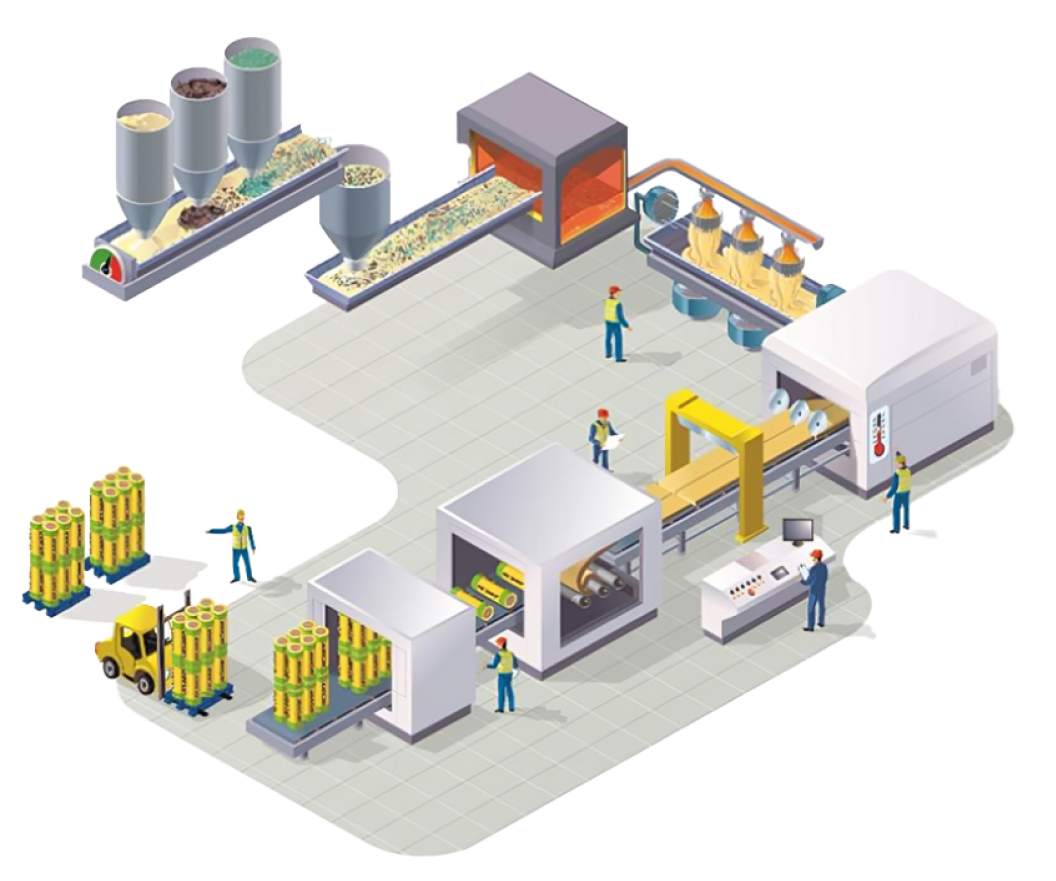

How Glass

Wool Works?

Fiberglass insulation has a

laminar structure with

interconnected air pockets.

This creates adequate

resistance to the air flow

path, thereby reducing

heat

and sound transmission.