There are 2 major requirements for any duct insulation :

This insulation is required to maintain the temperature of the air inside the ducts. If the air

is cooler (below ambient), heat gain must be prevented. If the air is warmer (above ambient),

heat loss from ducts must be prevented. This is achieved by insulating the duct as per ECBC

prescriptive guidelines, R ≥ 0.6 m2K/W.

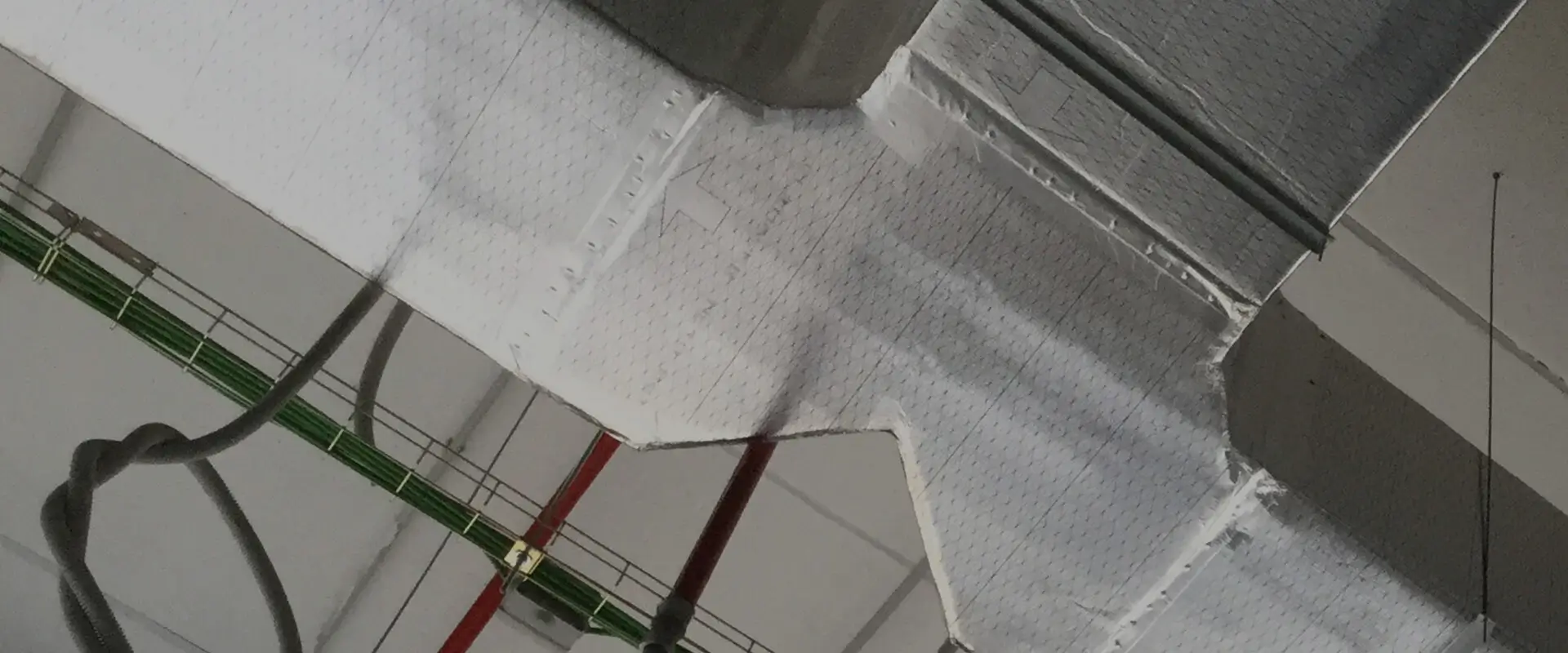

Overhead ducts are installed across the entire area of the building. If duct insulation is

combustible in nature, the risk of fire spread increases manifold. As per National Building Code

2016, duct insulation should be non-combustible and should not produce toxic gases in the event

of fire.

Another commonly observed problem is that of condensation. When the surface temperature of duct

insulation is lower than the ambient and humidity is high, moisture condenses, forms droplets

and starts to drip. Selecting the right type and thickness of insulation is critical to control

the effect of condensation over the ducts. Using a suitable vapour barrier to prevent any

moisture from entering the insulation will increase the its longevity.

Keeping in mind the above aspects, we offer glass wool insulation

-

High thermal resistance

High thermal resistance

-

Non-combustible, no fire propagation

Non-combustible, no fire propagation

-

Does not emit toxic fumes/smoke

Does not emit toxic fumes/smoke

-

Offered with factory applied FSK or Polypropylene facing (lamination)

Offered with factory applied FSK or Polypropylene facing (lamination)

Our insulation solutions with acoustic linings (such as tissue and glass cloth) effectively

reduce noise disturbances caused by air flow and turbulence within a duct while also providing

thermal resistance, prevention of condensation and fire safety.

By using our glass wool insulation with a glass cloth facing inside a duct, the noise is

absorbed by the insulation as sound travels through the porous facing. This reduces the noise

heard outside the duct while also offering excellent thermal resistance.

Flexible duct is ideal for short duct runs and intricate locations, offering a versatile connection between HVAC equipment and rigid ductwork. Its flexibility ensures efficient airflow in complex systems, making it perfect for spaces where rigid ducts cannot be implemented

Any HVAC system will also be accompanied by a dedicated AHU and MEP room. Due to the equipments

used in these rooms, noise is generated which can cause disturbance to surrounding areas.

Our Acoustic Board made of glass wool with tough black glass cloth facing is an excellent noise

barrier due to

its high NRC value. These are high density rigid boards which allow easy and fast installation

and do not require perforated metal covering.

The chilled water pipeline travels from the HVAC chilling plant to the AHU. It is crucial to

maintain the temperature of the pipe consistently along its length to ensure the correct

temperature of air at the output. This is essential for maintaining the effectiveness and

efficiency of the HVAC system.

We offer glass wool insulation in the form of pipe sections with appropriate vapour barriers.

Thes pipe sections are offered in various thicknesses depending on ambient and water

temperature, and also meeting prescriptive requirements of ECBC guidelines, with R values

ranging from 0.4 to 1.2 m2K/W.

We offer duct boards made of high-density glass wool insulation with suitable laminations on both sides. These boards can be easily converted into ducts with the help of dedicated tools. This non-metallic ducting system reduces the need for metal ducts.

Benefits & Features:

-

15% Lower Energy Consumption

15% Lower Energy Consumption

-

70% Lighter Than Metal Duct

70% Lighter Than Metal Duct

-

Fire Safe

Fire Safe

-

5 Times Faster Installation

5 Times Faster Installation

-

High Thermal Resistance

High Thermal Resistance

-

Good Sound Absorption

Good Sound Absorption