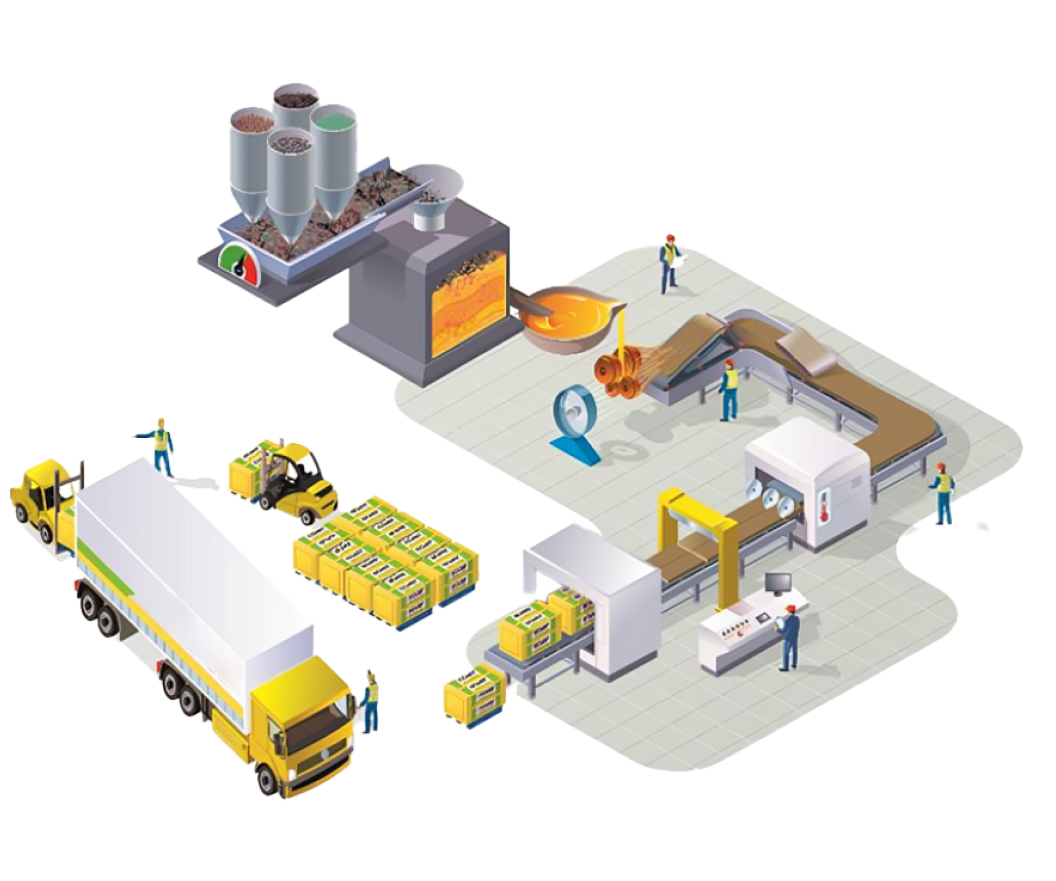

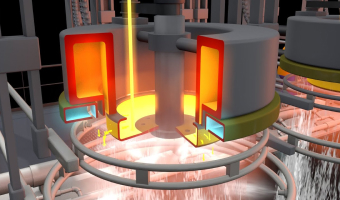

Stone wool, also known as rock wool, is manufactured by using volcanic rocks such as basalt

and dolomite as raw material. The raw material is heated to very high temperature using

fuel. The molten mixture thus obtained is passed through high speed spinners to form

fibers. The fibers are then impregnated with thermosetting resin binder.

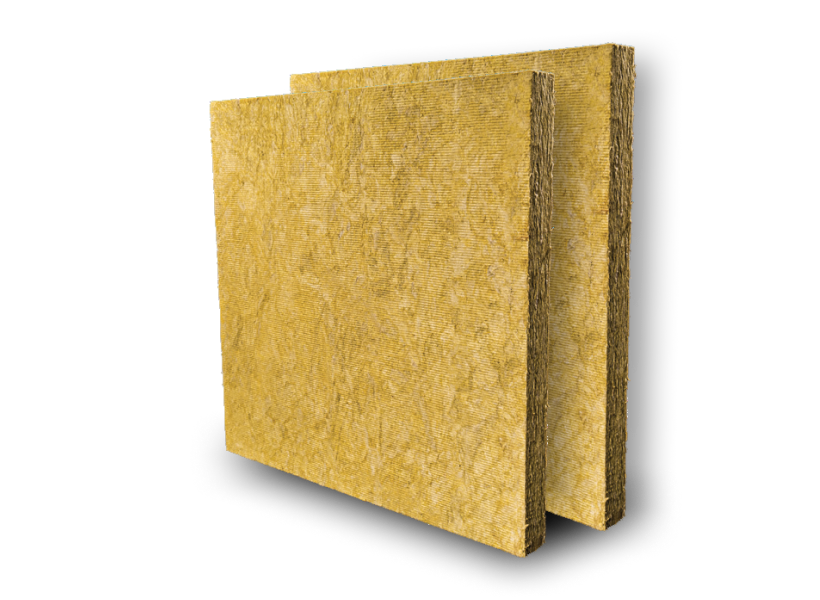

The fibers are then converted to

various

products such as LRB Mattress, RB Slab, Pipe section etc. of required density and thickness.

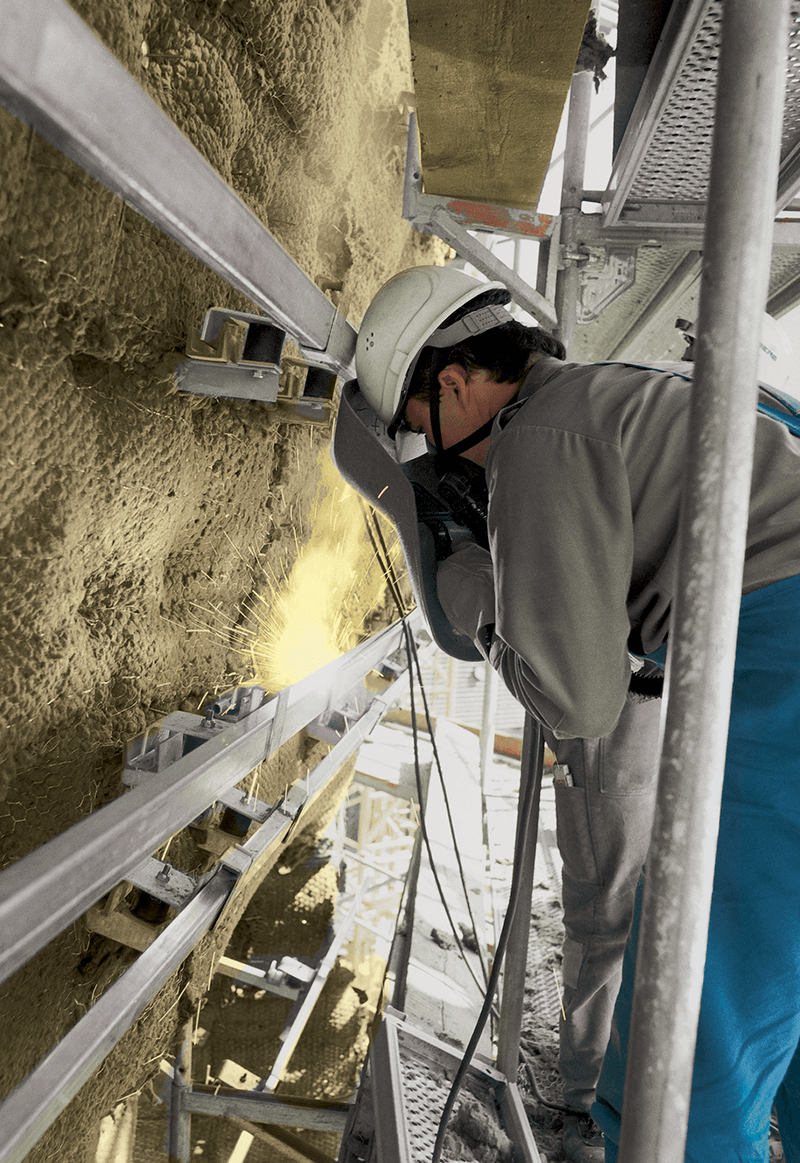

Product can be customized to various dimensions and offered with facings as per the

application.